FITCO’s woven narrow fabric division has initially started to produce tubulars for the automotive industry. We gradually became a highly respected partner and expanded our range of woven narrow fabrics.

Today we are able to propose a total solution using different kind of raw materials, weaving constructions and finishing techniques.

Max. width woven Narrow Fabric: 170mm

Manufacturing capabilities

- tapes

- webbings

- tubulars

- coating

- ‘zero’ defect control

Materials

- monofilament PP, PE, PES, PA

- multifilament PP, PE, PES, PES HT, PA

- aramide

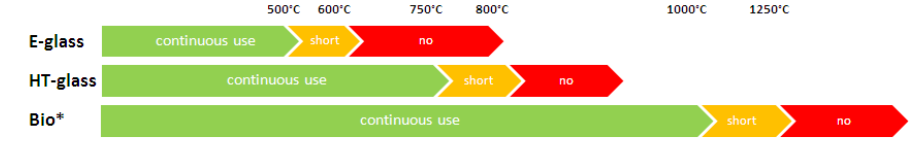

- glass

- other on request